MicroFactory Unveils Tabletop Robot Factory That Learns by Human Demonstration

Key Points

- MicroFactory delivers a tabletop manufacturing system roughly the size of a dog crate.

- The device contains two robotic arms that can be trained by direct human demonstration.

- Founders Igor Kulakov and Viktor Petrenko leveraged their manufacturing background to create the system.

- Hundreds of pre‑orders have been secured for applications ranging from electronics to niche food processing.

- A $1.5 million pre‑seed round values the company at $30 million.

- Units are slated to ship within the next two months.

- The company targets production of 1,000 units in its first year and plans rapid scaling.

- The platform blends human‑guided training with AI‑driven learning for efficient automation.

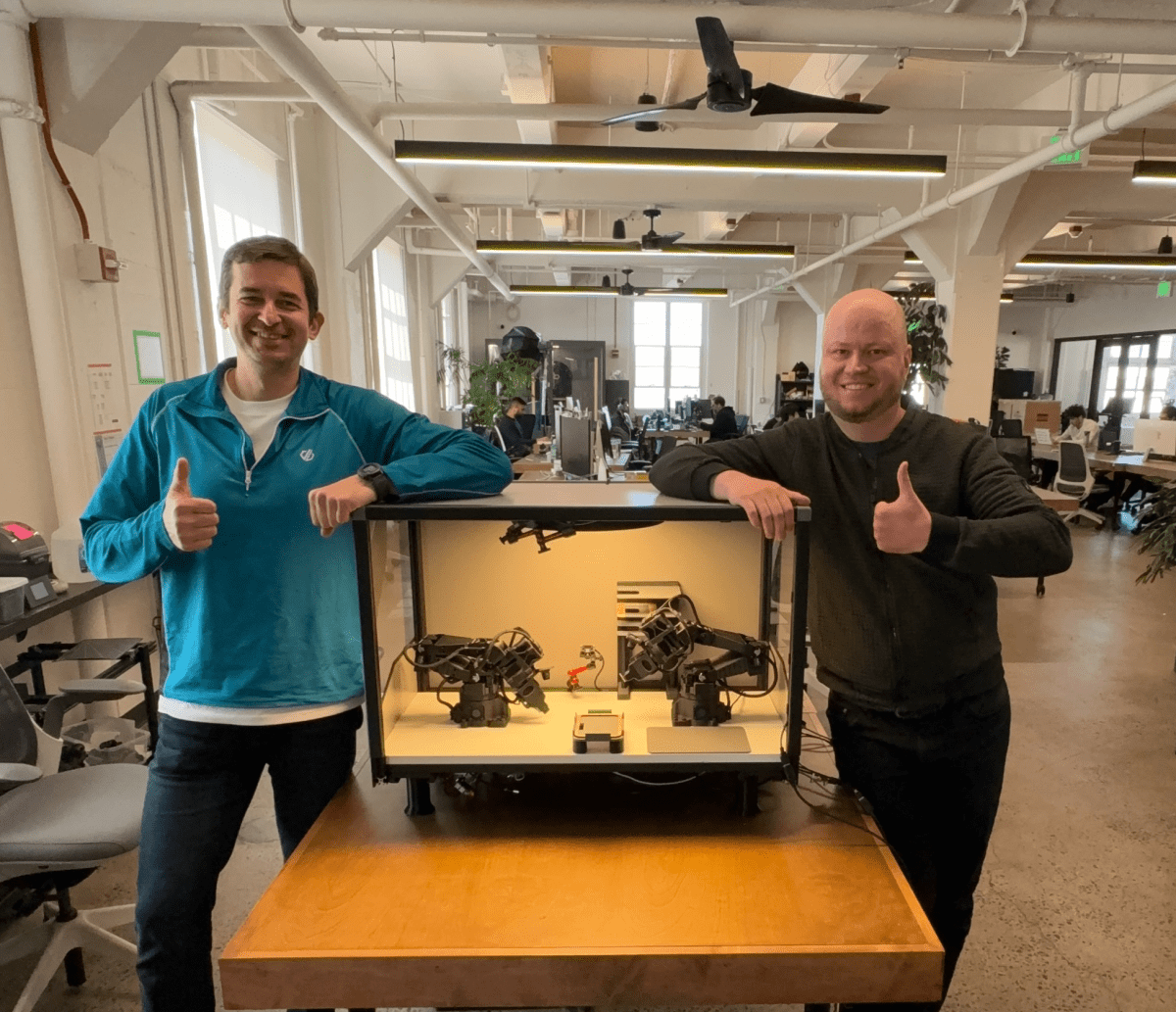

MicroFactory, a San Francisco startup founded by Igor Kulakov and Viktor Petrenko, has introduced a compact, tabletop manufacturing system that fits in a dog‑crate‑sized enclosure. The device houses two robotic arms and can be taught tasks through direct human guidance as well as AI‑driven learning. The founders, drawing on their experience running a lighting‑equipment business, designed the system to simplify precision work such as circuit‑board assembly and cable routing. With hundreds of pre‑orders, a $1.5 million pre‑seed round that values the company at $30 million, and plans to ship units within months, MicroFactory aims to scale production dramatically in its first year.

Overview of the Tabletop Factory

MicroFactory has built a general‑purpose manufacturing kit that occupies roughly the same space as a typical dog crate. The enclosed, transparent workstation contains two robotic arms capable of performing precision tasks, including circuit‑board assembly, component soldering, and cable routing. By keeping the system small and self‑contained, the company offers a visible, real‑time view of the manufacturing process, allowing users to monitor production as it occurs.

Training Through Human Demonstration and AI

The core innovation of MicroFactory’s platform is its ability to be trained by physically guiding the robotic arms through the desired motions. This hands‑on approach lets operators demonstrate complex sequences, which the system then captures and reproduces. According to co‑founder and CEO Igor Kulakov, this method is faster than traditional AI programming for intricate manufacturing steps, reducing the training time to a matter of hours. The system also incorporates AI models that continue to refine performance after the initial demonstration, blending human intuition with machine learning for efficient automation.

Founders’ Background and Motivation

Igor Kulakov and Viktor Petrenko previously ran bitLighter, a manufacturing business that produced portable lighting equipment for photographers. They encountered challenges training new employees to execute precise manufacturing processes correctly. When advancements in artificial intelligence suggested a feasible path to automate such work, the duo decided to develop a solution that would eliminate the steep learning curve associated with traditional factory staffing.

Market Reception, Funding, and Valuation

Since unveiling the prototype, MicroFactory has attracted hundreds of pre‑orders from customers seeking to apply the technology to a variety of use cases, from electronics assembly to niche applications like processing snails for escargot shipments. The startup recently closed a $1.5 million pre‑seed funding round that included investors from the AI sector and prominent entrepreneur‑investor Naval Ravikant. The round placed the company’s post‑money valuation at $30 million. The capital will be used to transition the prototype into a commercial product and to begin shipping units within the next two months.

Production Goals and Future Plans

MicroFactory’s growth strategy centers on scaling hardware production. The company aims to manufacture 1,000 units in its first year, roughly three units per day, and to increase output tenfold annually. In addition to expanding manufacturing capacity, the startup plans to hire new talent and continue improving the underlying AI models that power the system’s learning capabilities.

Implications for the Manufacturing Landscape

By offering a compact, easy‑to‑train robotic solution, MicroFactory challenges the prevailing trend of building large, human‑sized robots or pursuing full‑factory automation. The tabletop design lowers barriers to entry for small and medium‑sized enterprises that need precision automation without the overhead of traditional factory automation systems. If the company meets its production targets and maintains its current market interest, it could signal a shift toward more accessible, adaptable robotic manufacturing tools.