DeepMind Unveils RoboBallet AI to Streamline Industrial Robot Coordination

Key Points

- RoboBallet uses AI to coordinate multiple industrial robots with reduced computational complexity.

- Algorithmic scaling is linear with tasks/obstacles and quadratic with robot count.

- Performance matches human engineers in execution time while delivering solutions faster.

- Validated in both simulation and a real‑world test with four Panda robots on an aluminum workpiece.

- Enables rapid testing of factory cell layouts and robot selections.

- Allows on‑the‑fly reprogramming of work cells to handle robot failures.

- Promises greater flexibility and efficiency for manufacturing operations.

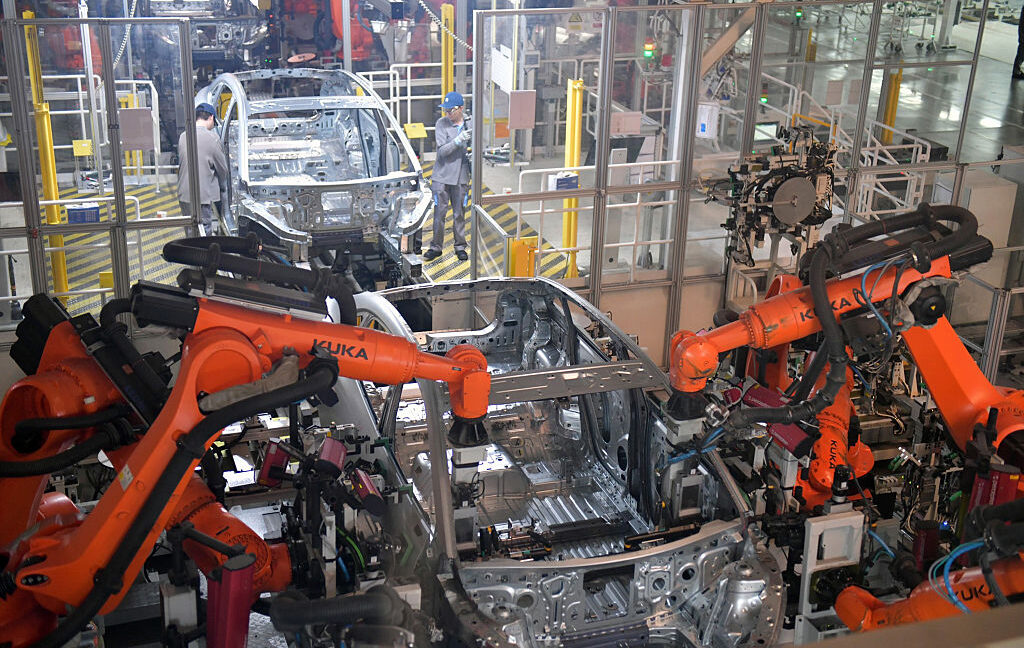

DeepMind's new RoboBallet system uses artificial intelligence to plan and coordinate multiple industrial robots with far lower computational overhead than traditional methods. The AI scales linearly with tasks and obstacles and quadratically with robot count, allowing rapid generation of task allocations, schedules, and motion plans. In controlled simulations and a real‑world test with four Panda robots working on an aluminum workpiece, RoboBallet produced results comparable to those of human engineers while delivering answers more quickly. The technology also enables designers to experiment with cell layouts and reprogram work cells on the fly, promising greater flexibility for manufacturing operations.

Scaling Computational Complexity

DeepMind's RoboBallet tackles a longstanding challenge in factory automation: the exponential growth of computational difficulty as more robots are added to a work cell. Traditional methods see the problem become practically intractable beyond a handful of robots. By contrast, RoboBallet's algorithms grow linearly with the number of tasks and obstacles and quadratically with the number of robots, keeping the problem manageable even as systems expand.

Benchmarking Against Human Engineers

To verify the quality of its plans, the DeepMind team compared RoboBallet's output with optimal task allocations and schedules generated for simplified work cells. The AI's execution times matched those of human engineers, delivering comparable solutions more quickly, though not surpassing human expertise.

Real‑World Validation

Beyond simulations, RoboBallet was deployed on a physical setup featuring four Panda robotic arms tasked with machining an aluminum workpiece. The AI‑generated plans performed as well in the real environment as they did in simulation, demonstrating the system's practical reliability.

Design Flexibility and Adaptive Operations

RoboBallet's speed offers factory designers the ability to test different cell configurations, robot selections, and layouts in near‑real time. Engineers can instantly see the time savings associated with adding another robot or swapping to a different model. Additionally, the system can reprogram a work cell on the fly, allowing other robots to take over when one fails, thereby enhancing operational resilience.

Implications for Manufacturing

By delivering rapid, high‑quality coordination plans, RoboBallet positions itself as a tool for scaling industrial automation without the steep computational costs that have limited broader adoption. Its capacity for swift layout experimentation and adaptive reprogramming could accelerate the design of more efficient, flexible manufacturing processes.